INTRODUCE

厂家介绍

广东kok电子竞技(中国)股份有限公司设备有限公司于1997年注册成立。总部位于广州市番禺陈涌综合开发区内,占地15000㎡,并于全国主要城市设立办事处,形成由中心点向全国各大中城市辐射的营销服务网络。多年来,kok电子竞技(中国)股份有限公司秉持以“以质量护卫安全,以信誉夯实发展”的企业理念,在消防设备的研发生产上不断构建专业化、多元化、系列化,凭借雄厚全面的技术力量、健全高效的质量保障、丰富灵活的现场经验、先进完备的检测设备、优质到位的售后服务赢得了广大客户的信任和青睐,引领着消防设备行业的规范。

了解详情 →

1997年

我司成立于

15000㎡

自有厂房占地面积

100+款

多门类的产品销售体系

50+项

消防产品认证,质量保证

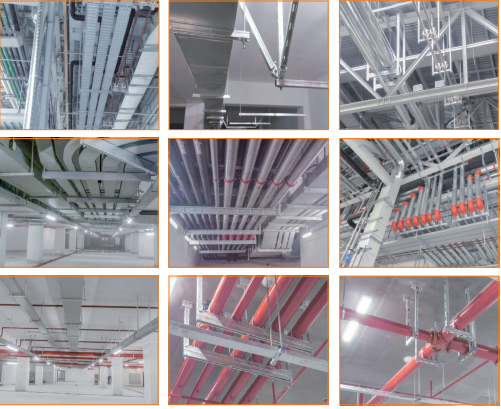

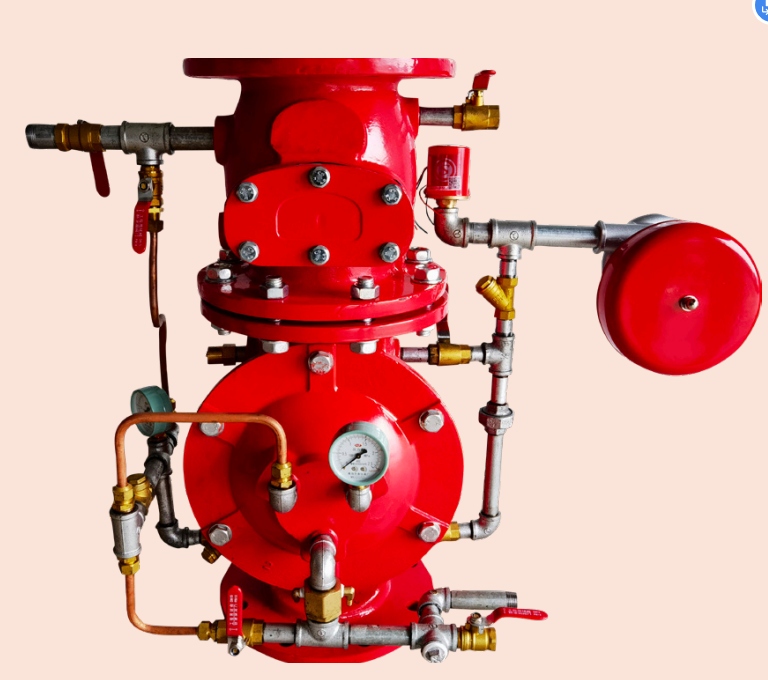

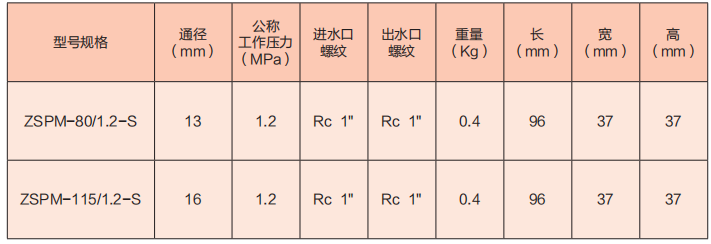

PRODUCT CENTER

产品中心

PRODUCT SERIES

产品系列

咨询热线:13602488119 潘总立即咨询

咨询热线:13602488119 潘总立即咨询

ADVANTAGE

产品优势

专注于七氟丙烷气体灭火系统研发、生产、销售、服务